Lead SWC bullets

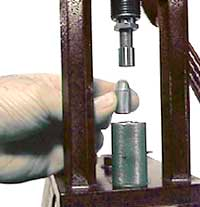

The most basic bullet is a lead semi-wadcutter style. The nose can be any shape, so long as there is a .015-.020 inch shoulder between the nose and the shank. This kind of bullet is formed in a straight hole die. A punch that slides up and down inside the die forms the base. Another punch with a cavity to form the nose shape pushes the lead into the die and applies pressure to flow the lead. The bullets include Airgun Pellets, and Shotgun Slugs with hollow bases.

This simple die is called the LSWC-1 or Lead SemiWadCutter. It takes one press stroke to form the finished lead bullet. The bullet can have a gas check, or a base guard base. Bleed holes in the side of the die allow you to set the volume and weight of bullet by extruding surplus lead. The nose and base punch can be changed to change the shape of either base or nose independently.

- Jacketed SWC bullets

A semi-wadcutter or shouldered style bullet can also be made with a jacket covering any portion of the shank (straight portion of the bullet, up to the start of the nose). This uses two dies. They are packaged as the "JSWC-2-S" or the "JSWC-2-H" set.- Die No. 1 is the CSW-1 core swage die. It adjusts the lead core weight, diameter, and makes the ends even and smooth.

- Die No. 2 is the CS-1 core seat die. It is fitted with an internal punch that forms the base, and an external punch which forms the nose. The edge of the nose punch makes a small shoulder between nose and shank. The jacket cannot go past this point.

- Die No. 1 is the CSW-1 core swage die. It adjusts the lead core weight, diameter, and makes the ends even and smooth.

- Lead bullet with smooth ogive

A lead bullet without a step or shoulder can be made in two dies.- Die No. 1 is the CSW-1 core swage die. It adjust the lead core weight, diameter, and makes the ends even and smooth.

- Die No. 2 is the PF-1 point form die. It has an ejection pin mounted in a punch head to push the bullet out of the die. The die cavity is not a straight-through hole. It is a semi-blind hole shaped like the bullet. The bullet is formed against the walls of the die, including the nose shape. This eliminates the need for a step or shoulder. It also means that there is no "nose punch". Instead, there is an ejector that pushes the bullet out by the tip.

- Die No. 1 is the CSW-1 core swage die. It adjust the lead core weight, diameter, and makes the ends even and smooth.

- Jacketed bullet with open tip, flat base

Three dies are used to make an open tip flat base jacketed bullet (no step or shoulder). This is the most commonly purchased set of dies and together, they are packaged as the "FJFB-3-S" or the "FJFB-3-H" set.- Die No. 1 is the CSW-1 core swage, which pre-forms the lead core and adjusts the core weight.

- Die No. 2 is the CS-1 core seater, which presses the lead core into the jacket. The external punch must fit the jacket ID snugly to seal pressure as the jacket expands. Different jacket thicknesses may require different external punches.

- Die No. 3 is the PF-1 point former, which has a cavity shaped like the bullet you want. It ejects the bullet by its tip. To change the shape, you must change this die. There is no "nose punch", just the ejection punch.

- Die No. 1 is the CSW-1 core swage, which pre-forms the lead core and adjusts the core weight.

- Jacketed bullet with lead tip, flat base

Lead tip bullets in a rifle ogive style are made using four dies. (Blunt lead tip bullets can be made in a three-die set, described above).- The first three dies are exactly the same as the above FJFB-3 three-die set. You can add the fourth die to an existing three-die set for lead tips.

- Die No. 4 is the LT-1 lead tip finishing die. It is a straight-hole die, similar to the core seater, but slightly larger bore size. The internal punch has a cavity in the tip to match the ogive shape of the point form die. But the die itself is only specific to a caliber (diameter). So you can use one caliber of lead tip die and different internal punches for other nose shapes, to match a different shape of point form die. (The lead tip die cannot be used by itself. It only "cleans up" the lead tip. It is not involved in shaping the rest of the ogive.

- The first three dies are exactly the same as the above FJFB-3 three-die set. You can add the fourth die to an existing three-die set for lead tips.

- Jacketed bullet with open tip and rebated boattail base

Jacketed open tip bullets are made with a three-die set as described above. To make a rebated boattail base, the core seating die is set aside, and two other special dies are used to seat the core while reshaping the straight flat based jacket. The four-die open tip rebated boattail set is called the RBTO-4-S or the RBTO-4-H (depending on which press it is made to fit).- Die No. 1 is our old friend the CSW-1 core swage, which is part of every set except the LSWC-1. It adjusts the weight, brings the diameter up to fit the jacket used, and makes smooth flat ends on the lead core.

- Die NO. 2 is a special kind of die called the BT-1. It has a straight bore with a tapered section to shape a boattail on the jacket as you seat the lead core. The internal punch is the diameter of the reduced base size. You seat the lead core into the empty jacket using this die, so that the lead pressure forms a tapered base on the jacket.

- Die No. 3 is a straight hole die simlar to the CS-1, but it has a slightly larger bore than the BT-1. It is fitted with an internal punch having a cavity in the tip. The cavity is shaped exactly like the RBT base. The tapered jacket from the BT-1 die will slip past the edge of the internal punch, fit into the cavity, and expand to exact shape including the edge of the punch. This makes a rebated boattail base with a concentric step.

- Die No. 4 is the point form die, or PF-1. It is used with a rebated boattail external punch, which pushes the seated core and jacket into the point form die and helps finish the rebate edge for a good gas seal. The same point form die can be used with a flat external punch and a core seat die to make flat base bullets.

- Die No. 1 is our old friend the CSW-1 core swage, which is part of every set except the LSWC-1. It adjusts the weight, brings the diameter up to fit the jacket used, and makes smooth flat ends on the lead core.

- Jacketed bullet with EITHER lead tip OR an open tip and rebated boattail base

Jacketed bullets with RBT bases and lead tips are made using five dies. To make a lead tip when you have a RBTO-4 open tip set, simply add the LT-1 lead tip finishing die. This is the same as you would do to make a lead tip if you had a flat base open tip three-die set (FJFB-3) and wanted to add lead tips. When a LT-1 die is added to the RBTO-4 die set, the five die package is called the "RBTL-5-S" or the "RBTL-5-H" set. (the -S is for the S-press, and the -H is for the larger Corbin presses such as the Hydro Press).- Die No. 1, 2, 3, and 4 are exactly the same as described above for the RBTO-4 set. You can stop there and have an open tip bullet, just by using a lead core length shorter than the jacket length.

- Die No. 5 is the LT-1 lead tip finishing die. It lets you add a factory-finished lead tip by using enough lead core relative to the jacket length so a little lead extrudes from the jacket as you form the ogive in the point form die. Then this surplus lead is reshaped in the LT-1 lead tip die.

- Die No. 1, 2, 3, and 4 are exactly the same as described above for the RBTO-4 set. You can stop there and have an open tip bullet, just by using a lead core length shorter than the jacket length.

- Jacketed bullet with EITHER a flat base OR a RBT base, and an open tip

You only use three of these dies for the flat base bullet, and four of them for the rebated boattail bullet. The difference is in the core seating operation. With a flat base, you set aside the BT-1 and BT-2 dies, and use the CS-1 core seater. With a rebated boattail base, you set aside the CS-1 core seater, and instead use the BT-1 and BT-2 dies to seat the lead core into the jacket. So, you can see that although this is a five-die set, the most you use on any one bullet will be four dies. The set is called the "FRBO-5-S" or the "FRBO-5-H", which means "Flat base or Rebated Boattail, Open tip 5 die set".- Die No. 1 is the core swage. You have read about it in the above. It still does the same thing, adjusting core weight.

- Die No. 2 is the core seater if you are making a flat base bullet.

- Die No. 2 is the BT-1 boattail preform die if you are making a RBT base bullet.

- Die No. 3 is the point form die if you are making a flat base bullet. You would be finished at this point.

- Die No. 3 is the BT-2 rebated boattail die if you are making a RBT base bullet. You would again use the same external punch as with the BT-1 die to seat the core again, refining the boattail and applying the step.

- Die no. 4 is the point form die if you are making a RBT base bullet. You would be finished at this point.

- Die No. 1 is the core swage. You have read about it in the above. It still does the same thing, adjusting core weight.

- Jacketed bullet with EITHER a flat base OR a rebated boattail base, and EITHER an open tip OR a lead tip.

OK, you can probably see where this is going: FRBL-6-S or FRBL-6-H sets have six dies, to allow you to use either three, four, or five of them on any given bullet, and make every style of bullet. The six-die all-style package has these dies:

OK, you can probably see where this is going: FRBL-6-S or FRBL-6-H sets have six dies, to allow you to use either three, four, or five of them on any given bullet, and make every style of bullet. The six-die all-style package has these dies:- Die No. 1 is the core swage. Covered in detail above, and in more detail on the Core Swage Page.

- Die No. 2 is the core seat die, if you want to make a flat base bullet. See details on Core Seater page.

- Die No. 2 could be the BT-1 boattail preformer, if you want to make a RBT bullet. See details on RBT-2 Add-on Set page.

- Die No. 3 could be the BT-2 rebated boattail finish die, for a RBT bullet. See RBT-2 Add-on Set page.

- Die No. 3 is the PF-1 point form die for a flat base sequence. See Point Form Die page for details.

- Die No. 4 is the PF-1 point form die for a RBT sequence. See Point Form Die page for details.

- Die No. 4 is the LT-1 lead tip finisher for a flat base sequence. See Lead Tip Die page for details.

- Die No. 5 is the LT-1 lead tip finisher for a RBT sequence. See Lead TIp Die page for details.

- Die No. 1 is the core swage. Covered in detail above, and in more detail on the Core Swage Page.

There you have it... all possible combinations of dies. If you think about how they work, you will see that all the die sets start with a core swage, to make an accurate weight of core. The weight of the jacket plus this core weight will be the weight of your bullet.

Just remember that the core seat die is ONLY used when you want to make flat base bullets. If you want to make RBT base bullets, use the combination of the BT-1 and BT-2 dies, which together are called the RBT-2-S or the RBT-2-H add-on set. You can add this set of two dies to any flat base die set in order to add RBT base capability.

Also, remember that the LT-1 lead tip finishing die does NOT create the ogive (nose curve). It is only used to finish the very tip of a soft point (lead tip) jacketed bullet. Adding another LT-1 lead tip die is only useful if you have a matching PF-1 point forming die. If you want to add another shape of bullet, in the same caliber, you need a different shape of point forming die. If you want to also make a matching lead tip, and have one lead tip die already in that caliber, all you need is the internal punch of proper lead tip shape.

Start writing here...

How To Swage Bullets Step By Step